Insulation is a crucial element in creating a comfortable and energy-efficient home. If you don’t insulate – your floor will be the same temperature as under your subfloor. Once you insulate under a timber floor, you thermally separate the two spaces, and your floor should be the same temperature as the inside of your home… No more freezing feet!

Insulating your timber floor also has a few other, lesser known, benefits:

- Improves air quality, by reducing dusty or moist air from the sub-floor entering the house

- Improves health by reducing mould, dust and respiratory triggers

- Reduces noise transfer from outside into the house

- Can reduce squeaky floorboard noise (particularly the spray foam option)

How does it work? Insulation acts as a barrier to heat flow. It helps to keep the heat in during winter and out during summer. It will help regulate the temperature of your home, reduce your bills, and enhance overall comfort.

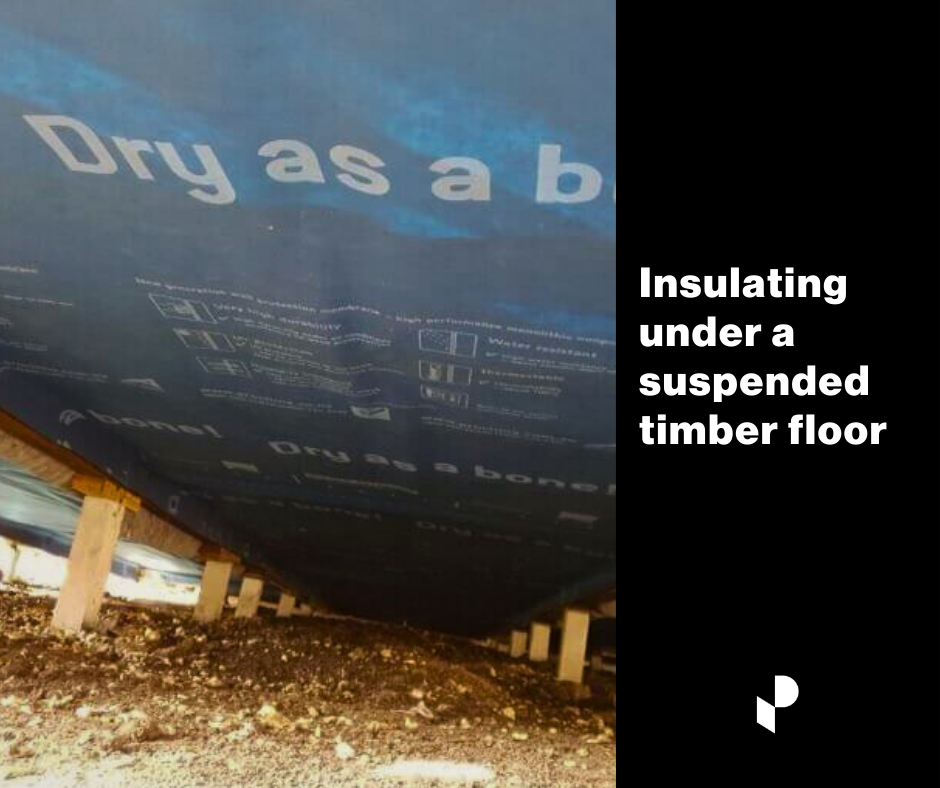

When it comes to insulating under your suspended timber floor, choosing the right option is essential for optimal thermal performance and moisture management.

As winter approaches, we’ve been asked by a few friends and clients about the best way to handle insulating under the floor – so here are our thoughts and comparison on four methods (let us know if you think we’ve missed any!).

Insulating under the floor tips

Coverage without gaps is key!

Before diving into specific insulation options, it’s important to highlight the significance of achieving continuous coverage with your insulation and no gaps. Even small gaps can have a huge impact on the effectiveness of insulation – so whichever way you go, any insulation installed beneath your suspended timber floor should create a seamless barrier to ensure maximum effectiveness.

Get an electrician to check your wiring before any new insulation

When you install insulation around electrical cables, the cable cannot dissipate heat as effectively. If there is too much power running through the circuit, you run the risk of overheating and fire.

Reputable insulation installers will ensure an electrical inspection before an install, and suggest solutions for reducing the loads. If doing a DIY install around any wiring – have your wiring checked beforehand.

Four insulation options under timber floors

Option 1: Insulation batts under the floor

These are typically made from fiberglass or mineral wool, and are a popular choice for DIY floor insulation. They offer good thermal properties and are relatively cost-effective. Installation involves fitting the batts snugly between floor joists, providing insulation between the timber structure and the subfloor.

It’s crucial to have a secure fixing, such as webbing or secure strapping, to avoid sagging or displacement over time. Insulation can be supplied in rolls or batts. Rolls are preferable as they are easier to install and reduce the chance of gaps.

We recommend choosing an insulation product that is designed for under the floor, as these often have a treatment to help reduce some drafts or air-leakage (not enough in our opinion). A few products available:

- Earthwool® FloorShield underfloor insulation, made by Knauf Insulation

- Ecomaster have a few products, and a very handy video series on how to install them

In general, this type of insulation is applied a lot as it is cheap and relatively easy to self-apply. It is also easy to remove and re-install for termite inspections. However, it has a few downsides:

- Insulation can sag or fall out over time. We recommend using a mesh to fix as it is the most robust.

- Rodents often find batts attractive, warm homes and will make nests

- A good install with no gaps is crucial to performance

- Although it can reduce draughts a little, batts alone will not deal with air-leakage – meaning that you will still lose some heat, and still have some air-pollutants entering from the sub-floor

Options that improve airtightness here include:

- Detailed filling all gaps between boards with a flexible silicon product (this will probably loose flexibility over time and gaps will re-appear), together wtih draught sealing skirting boards

- Laying over a second timber floor (running the beams in the opposite direction to ensure the gaps between the timber are not side-by-side)

being installed by a homeowner.

Source: facebook/my efficient electric house

Option 2: Spray Foam

Spray foam is draught-sealing and insulation in one. It adheres to surfaces, creating a tight seal and enhancing the overall airtightness of your home. Spray foam can also be applied in tight spaces, will not become a nest for rats and mice and will not sag over time.

We really like spray foam, provided it is installed by a reputable supplier and a quality product.

A summary of the benefits:

- Reduces floorboard squeak

- Stops all airflow between sub-floor and house, increasing internal air-quality and reducing dust, mould and allergens

- Rodent resistant

- 100% coverage

- Does not sag

- Fire-retardant

However, spray foam does have some downsides:

- It covers everything, including electrical wiring and plumbing. Any wiring in the floor needs to be down rated for contact, but it can make future access more difficult.

- Termite inspections are no longer possible, so may not be appropriate for high-termite activity areas.

- It isn’t appropriate in damp areas, as it can stop the flow of water or lock it in.

- It does off-gas immediately after install, and for a few weeks afterwards. Generally, within the floor cavity, this isn’t a problem.

Despite these downsides, its superior coverage and excellent air-leakage reduction means that it remains on of the best retrofit options for many homes.

insulation installed under a timber floor.

Source: Alexander Watson

Option 3: Residential Batts with Vapour Permeable Wrap

If you are going down the DIY route, this is our recommended option for dealing with insulation together with draught-proofing. Combine residential batts with a vapour-permeable, airtight wrap, such as Proclima Extasana. The wrap acts as a fixing mechanism, securing the batts in place and reducing the risk of sagging (and ideally, discouraging rodents – although we have not tested this). The permeable nature of the wrap allows moisture to escape, preventing the buildup of condensation and potential mould growth.

In order to get the best benefits from this method, the wrap needs to be taped at all edges to create a sealed underfloor environment. The wrap also needs to be fixed directly around the insulation without an air-pocket. This will prevent air escaping and create a controlled internal air environment. Although this step will take time, it will increase the effectiveness of your insulation efforts significantly as it will deal with both insulation and air-tightness.

This option provides the benefits of batt insulation while addressing air-leakage and moisture in one – something that will have a significant impact on the comfort and longevity of your home.

Option 4: Expandable Polystyrene (EPS) Panels

Expandable polystyrene panels like Expol can be condensed slightly to pack exactly between floor joists. Just like a polystyrene esky, these rigid panels provide excellent thermal insulation properties. However, their rigid and impermeable nature brings a few downsides:

- Tricky to cut to size when floor joists are warped or old

- It would require additional sealing with expandable foam to reduce air leakage

- Timber floors can expand and contract over time, potentially causing panels to fall out

- Rigid nature may create air-pockets between foam and floor where condensation and moisture form

Although they are popular due to the ease of handling them and no sticky fibres, in general these panels aren’t the best option for under your suspended timber floor.

Source: facebook/my efficient electric home.

Our recommendation for best underfloor insulation

- For DIYers: Option 3 – batts plus a vapour-permeable wrap.

- For professional install: Option 2 – quality polyurethane spray foam.

Both these options deal with airflow, moisture and insulation – crucial to maintaining underfloor comfort.

These are our own thoughts, and if you’re looking at updating your home – we recommend getting professional advice for your circumstances. If you’d like to work with us, request an obligation-free quote from our team or sign-up below to stay in the loop.

Have you used these solutions? Let us know how you went!